Clips for Grating

Installation- where possible, provide for a minimum of 40mm of bearing support at all grating

support points. Hold down clips should be used at the rate of one clips for every 0.5m 2 of grating

minimum, or at least 4 clips for any square or rectangular piece, or at least 3 for triangle piece.

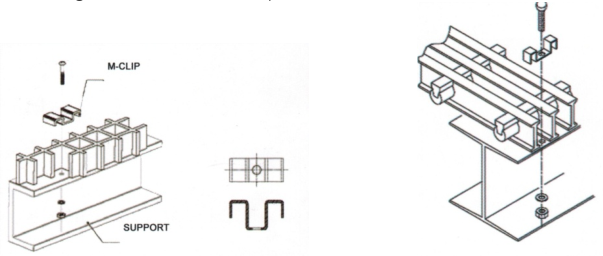

M Clips

M clips or saddle clips clamp two fiberglass grating load bars to the support. This provide excellent

holding capacity and because of this, are recommended for stair treads and most molded fiberglass

(square mesh, rectangular mesh, mini mesh)

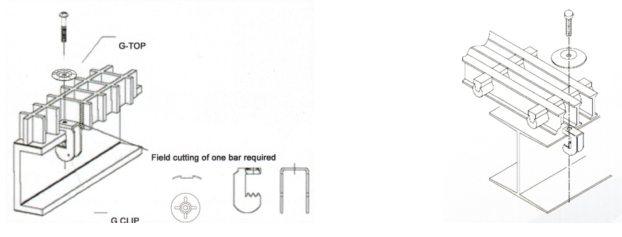

G Clips

When drilling the support member has to be avoided. G clips offer the solution. The lower jaw of the

clip grips the support flange when the bolt is torque. A heavier top clip then completes the assembly

to carry the loads. Providing excellent bi-directional holding capacity for square mesh grating.

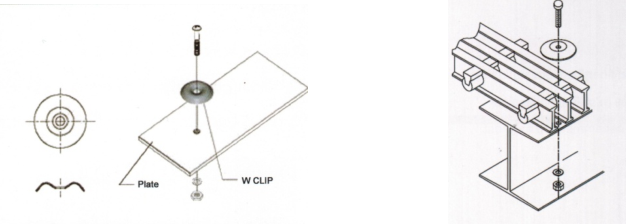

W Clips

This 40mm diameter fastener is used for holding down plates and covered fiberglass gratings. The W

clip’s recessed center allows the fastener to sit flush with this ADA compliant (<6.4mm high) hold

down clip.

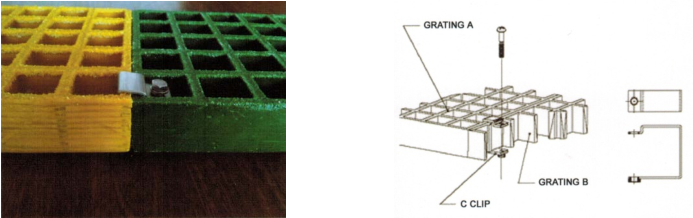

C Clips

C clips were specifically designed to be two panels fo molded fiberglass gratings together to minimize

differential defections when their joints fall between supports. C clips are also used in fiberglass

grating leg system for panel abutments. Lower nut is welded to clip so installation is from top side of

fiberglass grating to the floor.

PP Clips

PP Clips offer the solution for below surface attachment to pultruded grating.