Large span area always need safe solution which could provide enough loading for various scenes. That’s why we produce kinds of pultruded gratings. Higher fiber volume and better unidirectional machinery properties than molded grating can make it work well under same clear span. Meanwhile, pultruded grating has all the advantages which molded grating has.

Pultruded grating is manufactured by pultrusion with every panel of grating subjected to sequence of quality assurance inspections ensuring complete sealing of all joints,full wet-out of the glass rovings, consistent resin-to-glass ratios, and consistent non-skid features,complete traceability of resin batches and glass utilized in every panel is standard operating procedure.

|

|

|

|

|

|

Features of pultruded grating |

|

|

|

|

|

Higher stiffness Chemical Resistance Light Weight Ultra-violet Resistance Impact Resistance Non-Conductivity Fire Retardancy Non-skid & Safety Low Maintenance

|

|

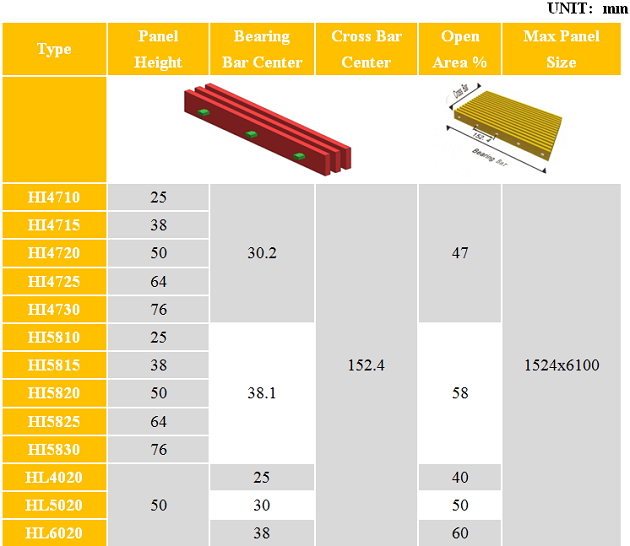

Heavy duty FRP grating

Pultruded heavy duty fiberglass grating is engineered for forklift and tractor trailer loads (up to standard truck, formerly H20) or high loads and very long spans which traditional fiberglass pultruded grating is not able to support. The highly engineered product is often used to replace steel gratings where the spans are typically greater. powercomposites pultruded heavy duty fiberglass grating come is 5 types of thickness: 25mm, 38mm, 50mm, 64mm and 76mm. You will also find that some of these fiberglass gratings and ADA and DDA compliant.