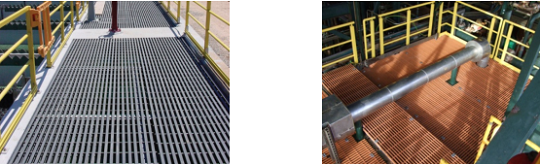

Large span area always need safe solution which could provide enough loading for various scenes. That’s why we produce kinds of pultruded gratings. Higher fiber volume and better unidirectional machinery properties than molded grating can make it work well under same clear span. Meanwhile, pultruded grating has all the advantages which molded grating has.

Pultruded grating is manufactured by pultrusion with every panel of grating subjected to sequence of quality assurance inspections ensuring complete sealing of all joints,full wet-out of the glass rovings, consistent resin-to-glass ratios, and consistent non-skid features,complete traceability of resin batches and glass utilized in every panel is standard operating procedure.

|

|

|

|

|

|

Features of pultruded grating |

|

|

|

|

|

Higher stiffness Chemical Resistance Light Weight Ultra-violet Resistance Impact Resistance Non-Conductivity Fire Retardancy Non-skid & Safety Low Maintenance

|

|

I-bar FRP grating

Pultruded industrial fiberglass grating is designed for use in a wide range of industrial applications that require strength and corrosion resistance. Manufactured with a high percentage of glass with laminate, industrial grating provides durability, extremely high unidirectional strength and stiffness. Due to its exceptional stiffness, it can be used with confidence where wide support spans are required.

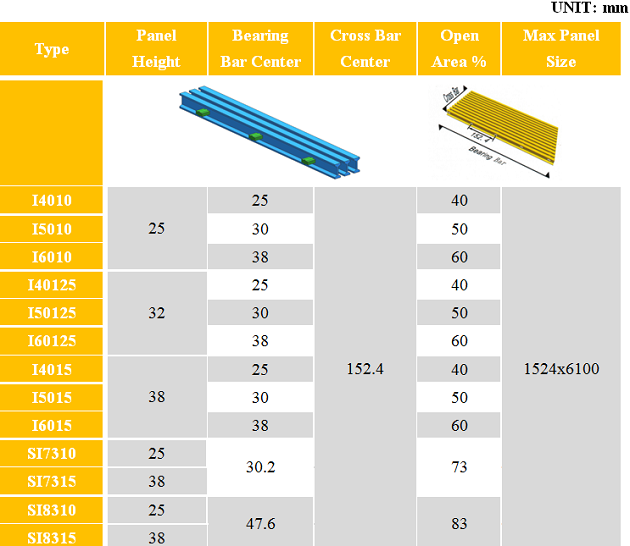

powercomposites pultruded industrial fiberglass grating comes in 25mm, 32mm, and 38mm thick in a bar configuration with 40%, 50% and 60% opening for most applications.

Standard I-bar sections are provided for applications where a close match to a steel or aluminum profile or to an existing installation is needed. powercomposites SI series is used widely in cooling tower and walkways due to its large open area. The bond cross bars are suited for use in low pedestrian traffic area. 73% and 83 open are allow for excellent ai